For a brief instant, researchers at Lawrence Livermore National Laboratory National Ignition Facility, NIF, in Livermore, California, created fusion Dec. 5, giving hope to the dream of a limitless clean energy source. An island-grown company, Luxel, took part in making that moment occur.

“I think this result gives new hope for it as an energy, it was proof of concept,” Travis Ayers, President of Luxel said.

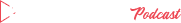

The role Luxel played in this potentially game-changing event was producing a thin proprietary polymer, or plastic-like, film that goes on the end of the laser’s target cylinder used in the experiment, which involved 192 lasers shooting into a tiny fuel cylinder to create an energy reaction.

“Our film is one of the last pieces to go on the target, so if our films are not reliable it wastes a lot of money and resources,” said Ayers. As a result, the filters go through rigorous qualification and quality checks before getting to NIF.

NIF, according to Ayers, is one of the most powerful energy facilities in the world. Housing the massive collection of lasers, the facility is the size of three soccer fields, Ayers said. Researchers fire them all up and the lasers creating a tremendous energy force that is delivered into a target and into a fuel capsule. The fuel capsule is compressed by the laser’s energy.

On Dec. 5, the fuel capsule imploded in on itself, rather than exploding. During that implosion for a brief heart-stopping moment, was fusion.

A press release by NIF explained fusion like this:

“Fusion describes what happens when the nuclei of light atoms such as hydrogen overcome the repulsive electrostatic force that keeps them apart. When the nuclei get close enough, the force that binds protons and neutrons together, the strong force, takes over and pulls the nuclei even closer together so they “fuse” into a new, heavier helium nucleus with two neutrons and two protons.”

According to the press release, the experiment surpassed the ignition threshold by producing 3.15 megajoules of fusion energy output from 2.05 megajoules of laser energy delivered to the target and touted the achievement as an unprecedented and game-changing breakthrough advancing the science of ensuring the reliability of the nation’s nuclear stockpile and stepping closer to the potential use of fusion as an unlimited clean energy source.

Up until now challenges have included a diverse performance of each laser shot to shot and the varying quality of the target, according to Lawrence Livermore National Laboratory physicist Annie Kritcher, lead designer and first author of the Design Physical Review E August 2021 paper. At that time, she wrote, researchers hoped to improve the laser, targets, and design, improving energy delivery to the hotspot while maintaining or even increasing pressure on the hotspot. Two years later those improvements are clearly paying off.

While the implications of the experiment are great, Ayers explained that if fusion were to be developed as an energy source it would not be at NIF, as that is not what that facility is designed for.

“It wasn’t designed to be an energy source, but to reach a net energy gain reaction,” he said.

There are a variety of paths toward fusion as an energy source, and funding backing at least three or four approaches. Those projects are going to know more going forward because of what NIF accomplished.

Luxel makes a variety of films and other specialized technology products. Luxel films typically range from five nanometers to one micrometer, and they have the ability to make filters out of approximately 70 different materials. The film for NIF however, is 500 nanometers thick. For reference, 100 nanometers is 10 percent of the width of a human hair or 200 times thinner than a kitchen foil like Reynolds wrap. These filters prohibit unwanted photons from going through.

Ayers gave the example of a camera. Taking pictures of extreme ultraviolet rays, like the sun, a camera will become blinded and the picture blurry. Put a thin filter on the lens and filter out those rays, and the camera suddenly has the ability to photograph the image, allowing the stunning close-ups of the sun available today.

The filter on the laser cylinders used by NIF works in a similar fashion, located on each end.

Orders for products like these filters are highly specialized. When a client approaches them, Luxel’s team works with the client, reviewing what the client’s project specifications are to come up with a product that will work. Production is small-scale as well, from 100 to 10,000 a month.

Luxel was founded on San Juan Island back in the 70s, by Gordon Steele. In the late 80s, Steele sold the company to Forbes Powell. Work with NIF began during that time period, in the 1990s. Ayers bought the business in 2007.

“I love trying to find new uses for technology, and continuing developing that technology,” Ayers said. He has an MBA and a mechanical engineering degree. Ayers had a job in the semiconductor industry when he said he had the wild idea to look for a business to purchase, and came across an ad for Luxel.

“I hadn’t even heard of Friday Harbor, but I haven’t looked back,” Ayers laughed.

The family packed up, moving from California to Friday Harbor, where they have become ingrained in the community ever since.

For Friday Harbor students excited about science or technology, Ayers said there are many cool areas of technology developing right now that kids could get into, working to solve some of the world, and society’s most difficult problems. Furthering development in fusion is just one example. Trying to refine and enhance computer chips, making them smaller and more efficient is another.

For those looking into a STEM career, Ayers said, “Seek out as much information as you can to set yourself up for a career. Sometimes Friday Harbor seems limited, but resources can be found. Local teachers are great, and online information can be a supplement.”